Supplier Onboarding Strategies for Reducing Supply Chain Risk

By integrating risk management practices into your supplier onboarding process, you can ensure that new suppliers align with your company's expectations for cybersecurity, financial and reputational health, ESG standards, and compliance with government and regulatory requirements.

In this article, we explore some of the best practices for establishing a risk-aware supplier onboarding process. Note that these guidelines use the term "supplier" to refer mainly to third parties that provide physical (i.e., non-IT) goods and services.

What Is Supplier Onboarding?

Supplier onboarding is the process by which a company adds a new supplier to its procurement and supply chain system. It encompasses all steps from conducting pre-contract due diligence and collecting and centralizing key profile information about the supplier, to contract review and approval. A major goal of supplier onboarding is to ensure that new suppliers have the security, operational, and compliance controls necessary to mitigate risk – thereby ensuring the supply chain's overall efficiency and reliability.

Taking supplier risk into account during onboarding can be the key to proactively avoiding business disruptions and reducing the impact of supplier data breaches, ESG issues, financial problems, and other incidents on your organization.

Why Is a Structured Supplier Onboarding Process Important?

A structured supplier onboarding process ensures that new suppliers can meet security, operational, and compliance requirements, effectively remediate and mitigate risks, and protect the supply chain's overall efficiency. Key objectives of supplier onboarding processes include:

- Ensuring business stability by monitoring financial data, such as credit ratings, bankruptcy history, turnover records, profit and loss statements, and investment activity

- Reducing the risk of data breaches that could affect your systems by identifying cybersecurity vulnerabilities and assessing IT controls

- Protecting your reputation by screening for environmental violations, unethical labor practices, and other ESG issues

- Identifying operational and compliance risks stemming from government sanctions, adverse media, negative news, and leadership changes

- Getting ahead of downstream supply chain disruptions by mapping 4th- and Nth-party relationships and technologies in use

Best Practices for Risk-Aware Supplier Onboarding

Effectively onboarding and mitigating risk from suppliers is a key aspect of corporate risk management. Before a supplier can be fully onboarded, it’s important to assess and categorize the risks they pose to your organization. Here are seven best practices to follow:

Evaluate Supplier Risk Early in the Selection Process

Weighing risk as a consideration during supplier sourcing and selection can help to ensure a smooth onboarding process. Consider candidates that not only fit your business requirements but also meet minimum standards for security, compliance, operational controls, and reputation. At this early stage, conducting a quick check of news coverage, legal databases, and public filings can flag high-risk suppliers and save you time and resources later in the onboarding process.

Compare Shortlisted Suppliers with Risk-Aware RFx Processes

Adopt a risk-aware RFx management program that automates and standardizes your RFI and RFP processes for evaluating suppliers. The RFx process is an opportunity to gather initial information from prospective suppliers about their internal security controls, ESG programs, incident response processes, and other risk management capabilities. For further assurance, pair RFx response data with an external risk profiling snapshot, which can reveal information about fourth-party technologies in use, ESG scores, data breach history, and business, reputational, and financial performance.

After evaluating initial controls and risk summaries, assign a preliminary risk rating to each supplier, aligning with your business priorities. For chosen suppliers, integrate risk findings into their profiles for more informed contract negotiation and management.

Streamline and Automate Contract Lifecycle Management

When new suppliers are selected, be sure to have a sound contract lifecycle management process in place. A structured, automated approach to contract management enables organizations to speed the onboarding process and reduce third-party risk by:

- Reconciling edits from internal stakeholders and suppliers

- Updating redlined copies and managing version control

- Coordinating procurement, legal, and finance teams for streamlined reviews

- Ensuring that terms and SLAs are consistent across similar suppliers

Contract lifecycle management solutions can also help after onboarding by facilitating SLA reviews and monitoring contract terms for renewal or termination.

Build a Central Database of Suppliers

A key goal of supplier onboarding solutions is to centralize supplier data, enabling key stakeholders to access it easily. The process typically starts with manual data entry or bulk uploads into a supplier risk management solution. Integrating data from existing procurement or supplier management solutions via API connections, spreadsheets, or other methods is crucial.

Effective onboarding programs require involvement from various teams, including accounts payable, procurement, finance, and supplier management. Ensuring your supplier risk management tool offers role-based access for updating supplier profiles is essential.

Strategically Map Fourth-Party Relationships

Centralizing supplier data also helps identify dependencies that could potentially introduce risk from 4th parties deeper down the supply chain. When identifying fourth-party relationships during procurement and due diligence, it's crucial to have a solid strategy since direct interaction with them often isn't possible. When engaging in a competitive bidding process with potential suppliers, be sure to include questions about fourth-party relationships in your request for proposal (RFP).

As soon as you have narrowed your options to a finalist, you'll need to inquire further during the supplier onboarding process. Besides spotting the fourth parties that your supplier will use, you should also ask pertinent questions about each. For example, do your primary suppliers mandate information security certifications from their suppliers?

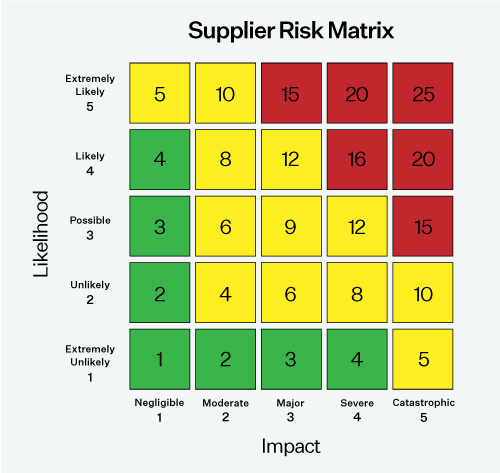

Tier Suppliers Based on Risk

Tiering potential suppliers based on the inherent risk that they pose represents an excellent opportunity to drive efficient allocation of resources. Categorize suppliers who play a smaller role in your supply chain and/or don't supply essential goods or services for daily operations into a lower tier. This approach enables you to use fewer resources on their risk assessments and onboarding process.

Conversely, identifying suppliers with high degrees of inherent risk can enable you to spend additional cycles conducting due diligence. Here are a few key questions you can ask about potential suppliers to help correctly tier them based on risk:

- Are the goods or services being supplied necessary for day-to-day business operations?

- If there was a sudden financial catastrophe or disruption at the supplier, how long would it take to begin to disrupt business operations at my organization?

- What type of data will be collected and retained by the third-party supplier?

- Does the supplier pose any obvious ESG, reputational, or compliance risks?

Mitigate Unacceptable Risk Before Final Onboarding

At this stage, you should have a comprehensive supplier profile that includes beneficial ownership, financial performance, CPI scores, Modern Slavery statements, industry and business insights, and maps of any potentially risky 4th-party relationships. You now need to work with them to remediate or mitigate any risks that fall outside of your organization’s risk tolerance threshold.

In addition to internal third-party risk policies, your organization may have compliance or regulatory obligations to meet. Once a supplier has been successfully onboarded, you can use the insights generated from this process to initiate a regular cadence of internal assessments supplemented by continuous monitoring intelligence.

100 Essential Onboarding & Offboarding Tasks

Download the Ultimate Third-Party Onboarding & Offboarding Checklist to understand the essential insights and tasks required to securely onboard and offboard vendors and suppliers.

Keys to a Strong Supplier Onboarding Process

Effective supplier onboarding is critical for minimizing risk, enhancing supply chain performance, and achieving competitive advantage. It requires a structured approach, with clear processes and guidelines, to ensure that new suppliers are capable, compliant, and aligned with the company's strategic goals. Here are some key characteristics of successful supplier onboarding programs:

- Streamlined Processes: Develop a standardized, efficient onboarding process that is clear and straightforward for both the company and the supplier.

- Clear Communication: Maintain open lines of communication throughout the onboarding process. Articulate expectations, timelines, and requirements to avoid misunderstandings.

- Technology Utilization: Leverage technology and automation to streamline the onboarding process, improve data accuracy, and maintain a centralized repository of supplier information.

- Performance Metrics and KPIs: Establish clear performance metrics and key performance indicators (KPIs) for new suppliers. This helps in monitoring their performance and ensuring they meet the company’s standards.

- Continuous Improvement: Regularly review and update the onboarding process based on feedback and changing business needs to ensure it remains effective and efficient.

- Compliance and Ethical Standards: Ensure that suppliers adhere to compliance and ethical standards, including labor practices, environmental regulations, and anti-corruption laws.

- Collaboration and Partnership: Approach supplier relationships as partnerships. Foster collaboration and mutual growth to build long-term, sustainable relationships.

Streamline Supplier Onboarding with a Unified SRM Platform

For organizations with extensive supplier networks and complex supply chains, adopting a unified Supplier Risk Management (SRM) system is essential for enhanced control and oversight.

Streamlining supplier onboarding with a comprehensive SRM solution enables your team to:

- Use intelligence for detailed supplier evaluation and comparison

- Integrate contract lifecycle management into supplier onboarding processes

- Build a central supplier profile, complete with firmographics and risk information for use by multiple stakeholders

- Extend visibility to fourth and Nth parties in the broader supplier ecosystem

- Profile, tier, and categorize suppliers according to risk insights

- Enforce remediations and report on risk to aid in continued supplier evaluations

- Continuously monitor suppliers to stay ahead of potential cyber, business, and financial risks.

Next Steps: Automate Supplier Onboarding

Integrating suppliers doesn't have to be difficult. With smart planning and an automated system, you can quickly see benefits from new suppliers, reduce risks from third parties, and build stronger business relationships. Find out more about Prevalent’s supplier risk management solution or request a demo today.

-

Ready for a demo?

- Schedule a free personalized solution demonstration to see if Prevalent is a fit for you.

- Request a Demo